Services

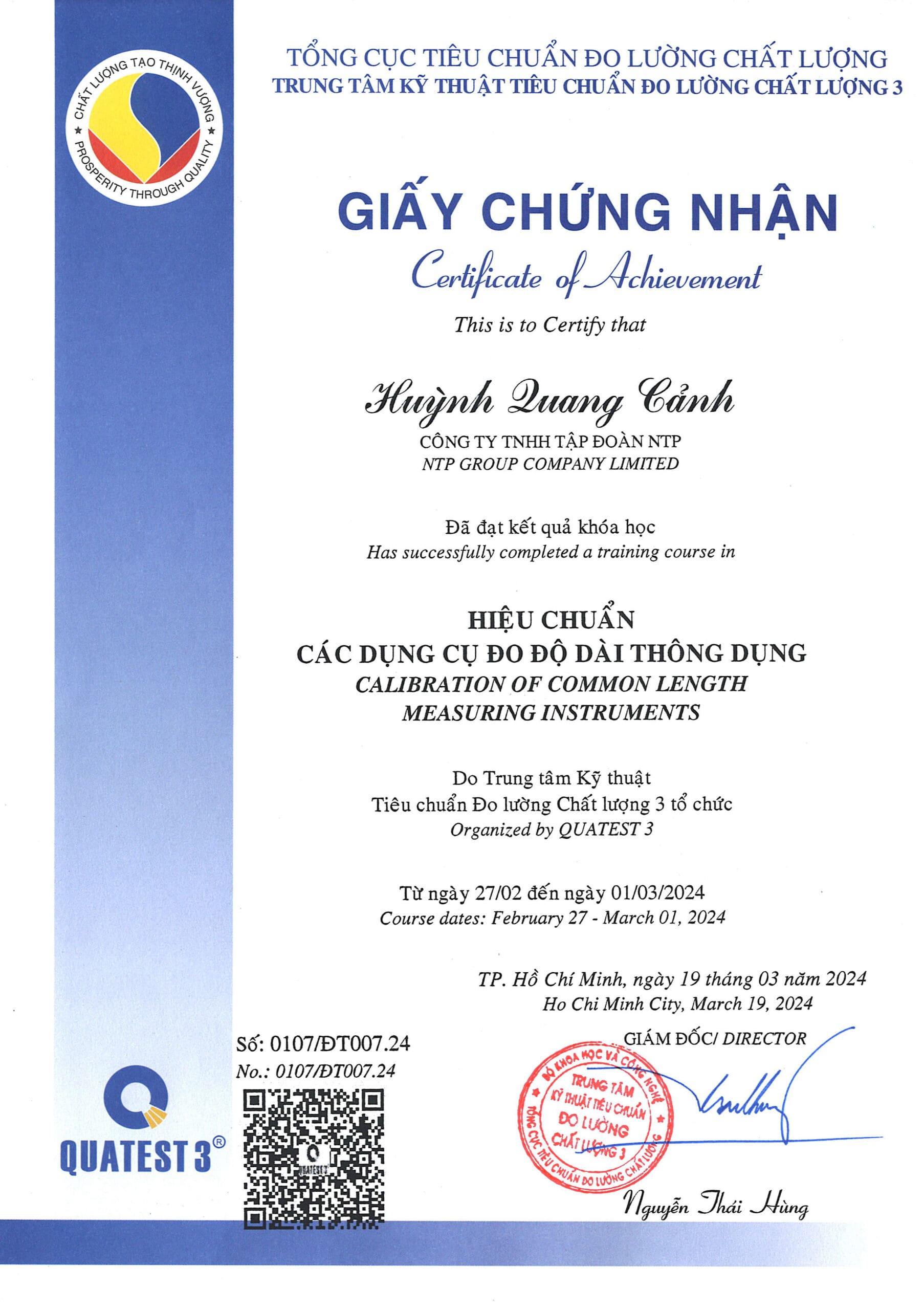

Laser Cutting

- Mild Steel (20mmT)

- Stainless Steel (18mmT)

- Aluminium (16mmT)

- Brass (10mmT)

- Copper (8mmT)

- Titanium (10mmT)

SIZE / CAPACITY

- Up to 3070mm x 1550mm

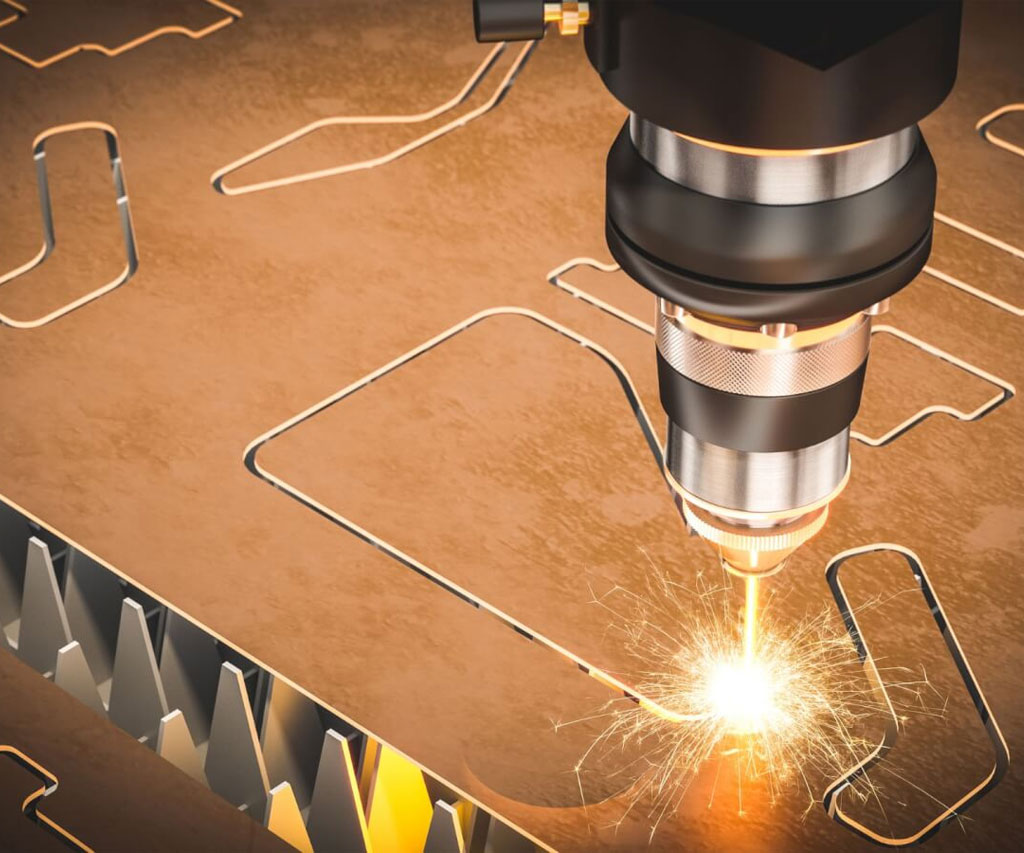

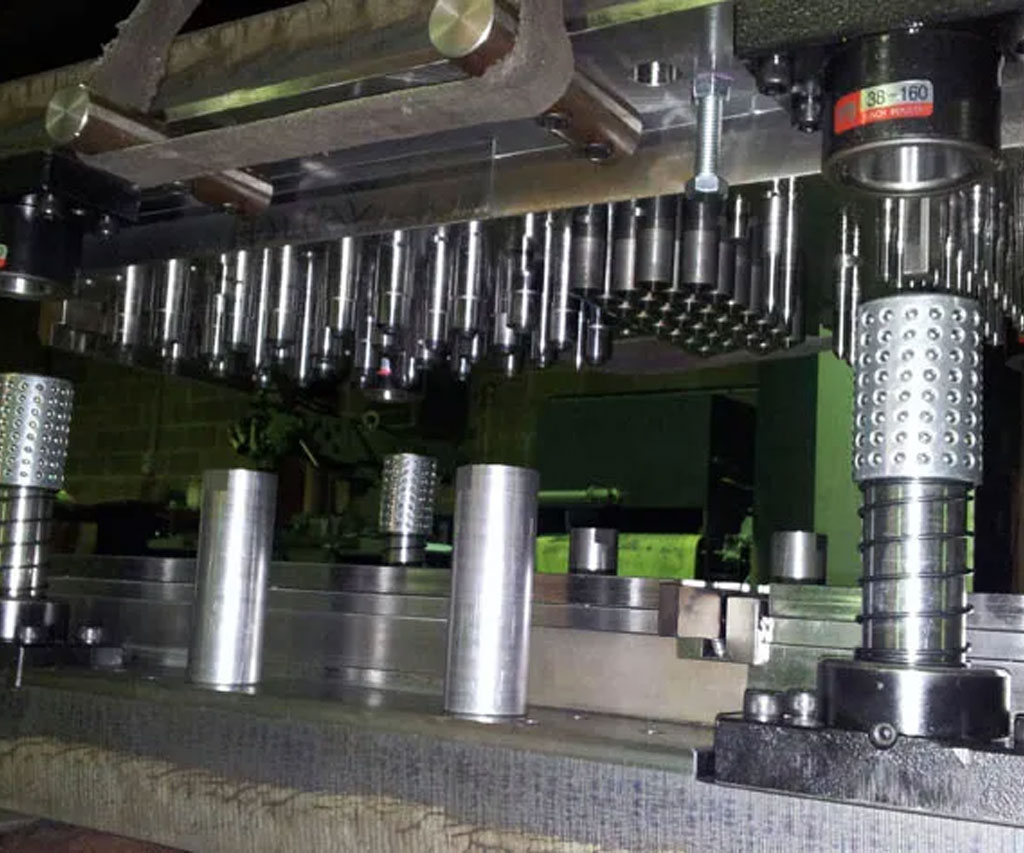

EDM Wire Cutting

- Mild Steel

- Stainless Steel

- Aluminium

- Brass / Bronze

- Copper

- Titanium

SIZE / CAPACITY

- Up to 820mmL x 560mmW x 500mmH

- Cutting up to – 550mmL x 450mmW

Combination Laser Turret Punch

Tap applications for mild steel, stainless steel & aluminium.

SIZE / CAPACITY

- Up to

CNC Lathe (Turning)

- Various Metals

- Nylons

- Composites

- Various other Plastics

MACHINING CAPABILITY

- Up to 480mmD swing over bed

- Up to 700mm between centres

CNC Milling (Machining)

- Various Metals

- Nylons

- Composites

- Various other Plastics

MACHINING CAPABILITY

- Axis X:1050mm, Y:510mm, Z:560mm

- Rotary Table (4th Axis)

- Table Capacity up to 1000kg

Robotic Welding

State of the art 6 axis robot welding for white steel and aluminium.

- Max accessible distance: 1598mm

- Performance (according to ISO 9283)

Sheet Metal Fabrication

MACHINES

- Guillotines

- Horizontal Bandsaws

- CNC Cutter / Router

- Laser Cutting / Engraving

- CNC Turret Punches

- Press Brakes

- Hydraulic Presses

- Pipe Benders

- Various Welding (TIG, MIG, Laser)

CNC Pipe / Tube Bending

- Mild Steel

- Stainless Steel

- Aluminium

- Brass

- Copper

BENDING CAPABILITY

- Bending Capacity: 150mmD x 8mmW

- MAX Bending Radius: 500mm

- MAX Bending Angle: 190º

Hydraulic Presses

Various hydraulic presses ranging from 30 tonne to 200 tonne.

TOOLING CAPABILITY

- Bed Size up to 1830mmL x 1000mmW

- Die / mold height up to 850mm

- Stroke up to 300mm

Overhead Cranes

Our workshop consists of 5 over head beam cranes to easily maneuver large jobs from one area to another.

(3x) 3 Tonne Beam Cranes

(2x) 5 Tonne Beam Cranes

Steel Cutting & Welding

NTP Group have a range of metal cutting saws so cut a wide range of materials and sizes.

Our welding facilities consist of a range of welding capabilities including:

MIG Welding . TIG Welding . Laser Welding . Spot Welding

ARC Welding . Oxy/Acetylene brazing

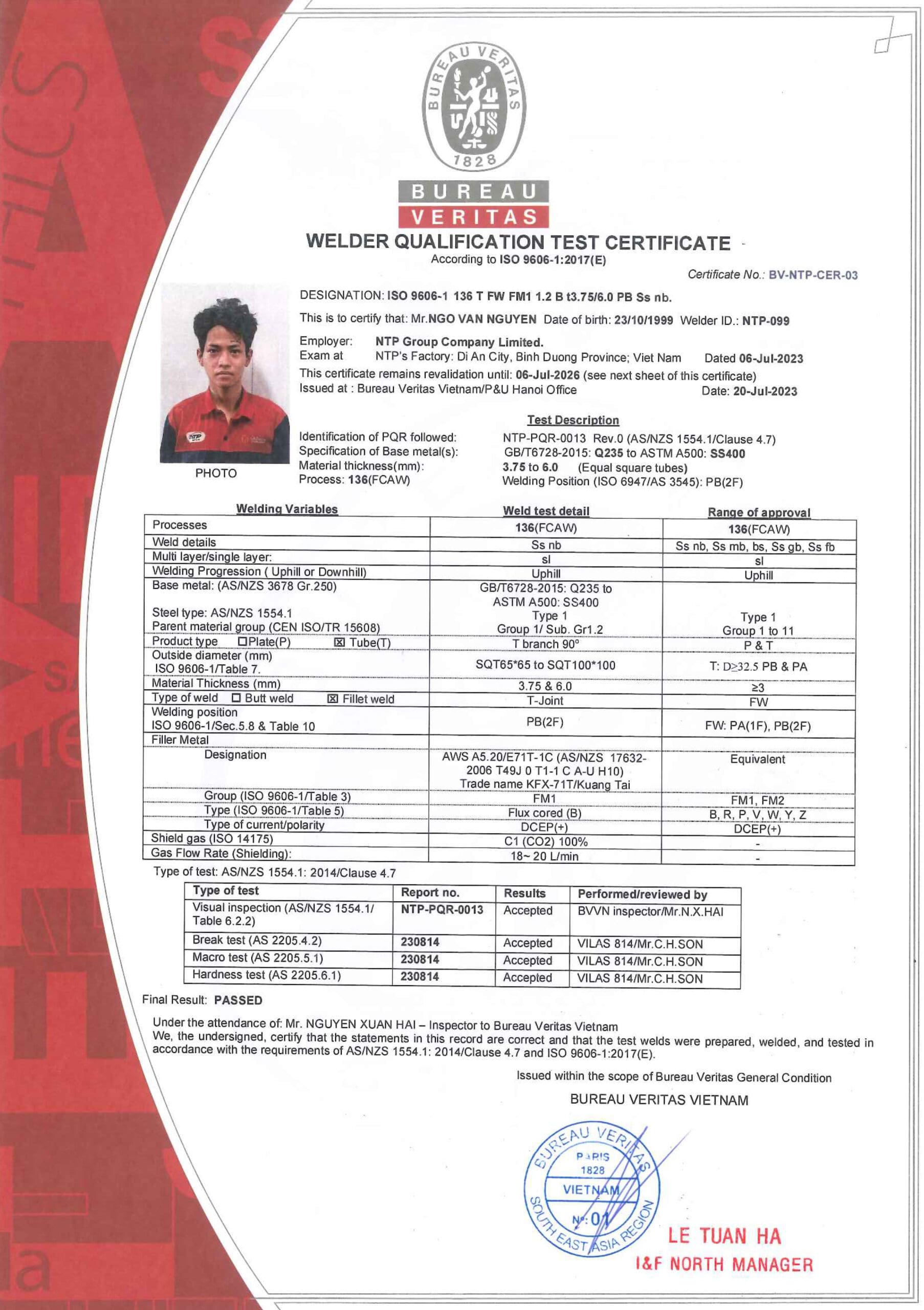

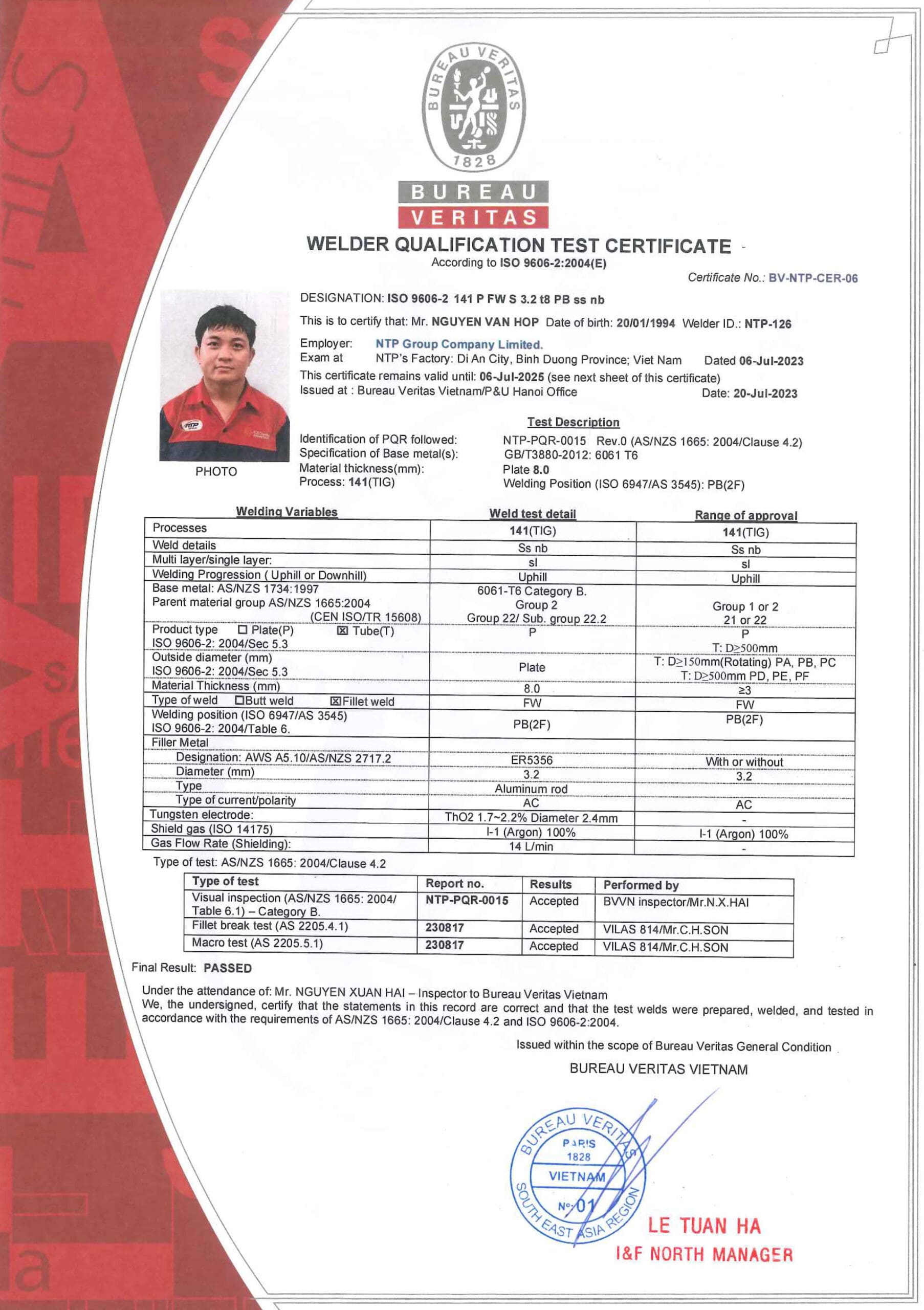

For specific and specialised products that our customers require, we apply ISO welding procedures, ISO 15609-1, ISO15614-1. In addition NTP welders are qualified with welding standard ISO 9606-1 to complete such products.

Powder Coating System

NTP has In house powder coating and wet spray coating facilities. Only the highest quality powder is used (www.akzonobel.com).

Testing is undertaken regularly to ensure the quality of the finish is maintained. Tests include:

Appearance

Colour

Hardness

Gloss

Adhesion

Gravelometer

Salt Spray

We also offer Hot dipped galvanized , Electro Zinc Plating and E coating through out-sourcing to qualified local companies.

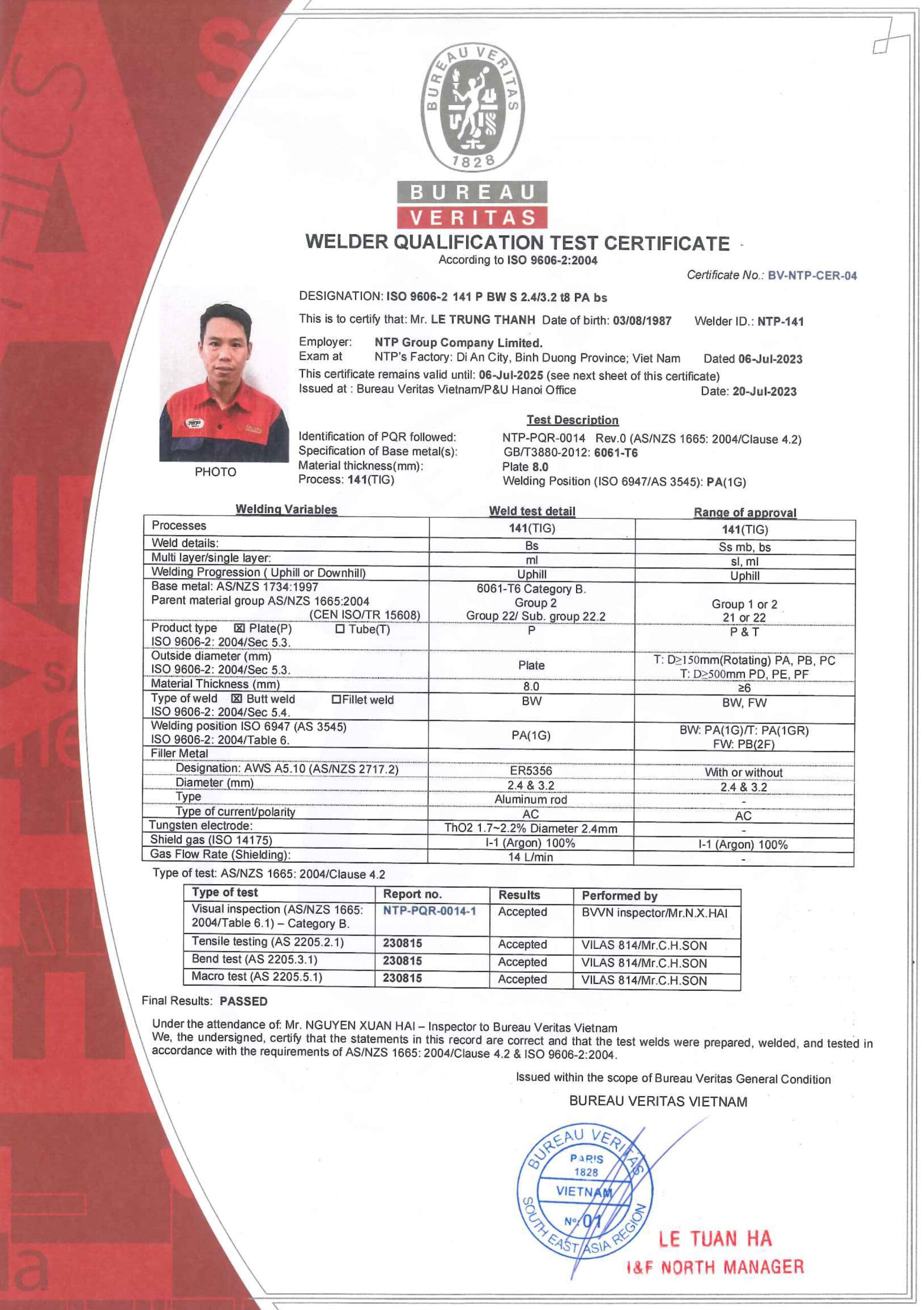

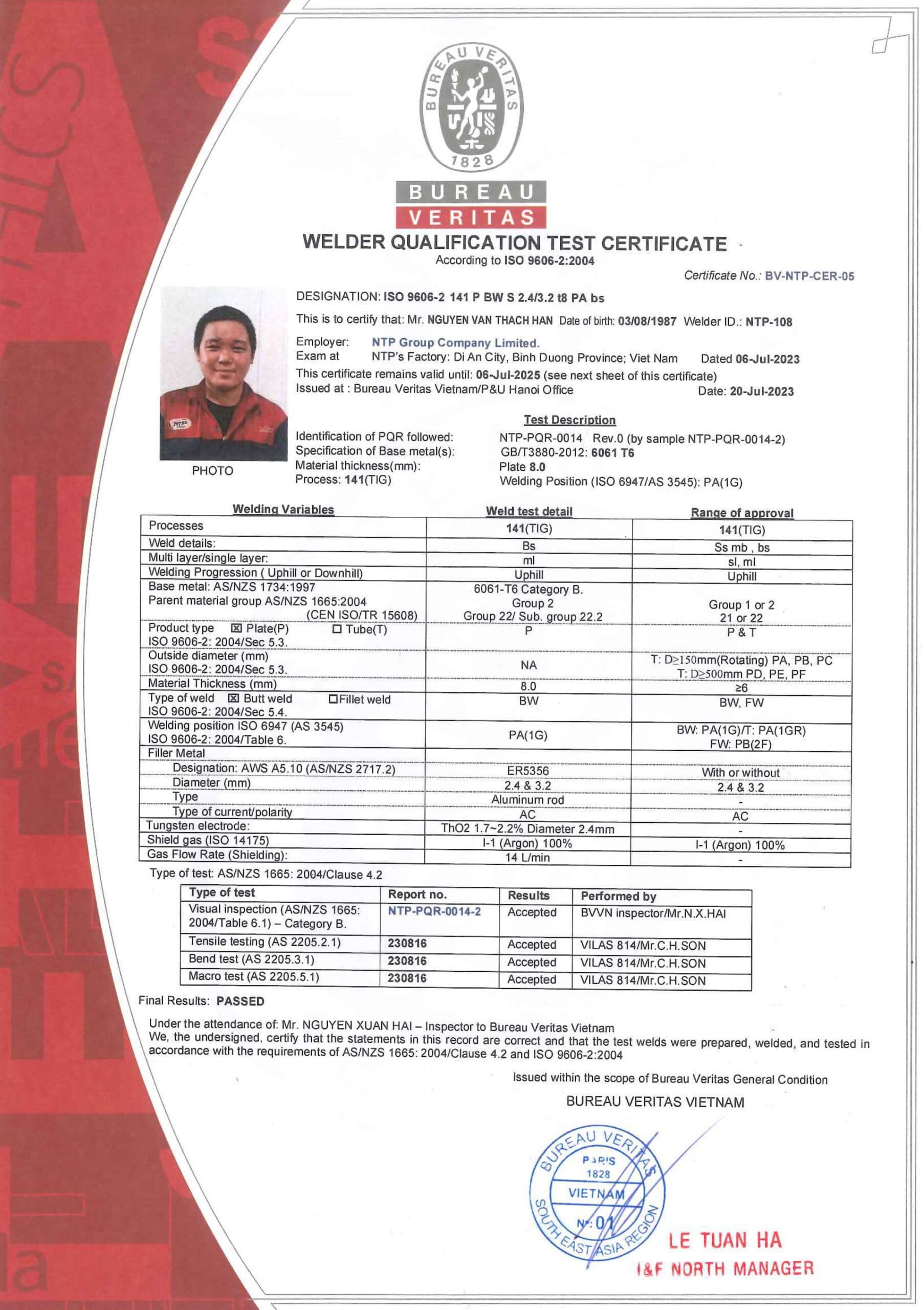

Certified Welder Certificates

Quality Control Cerificates