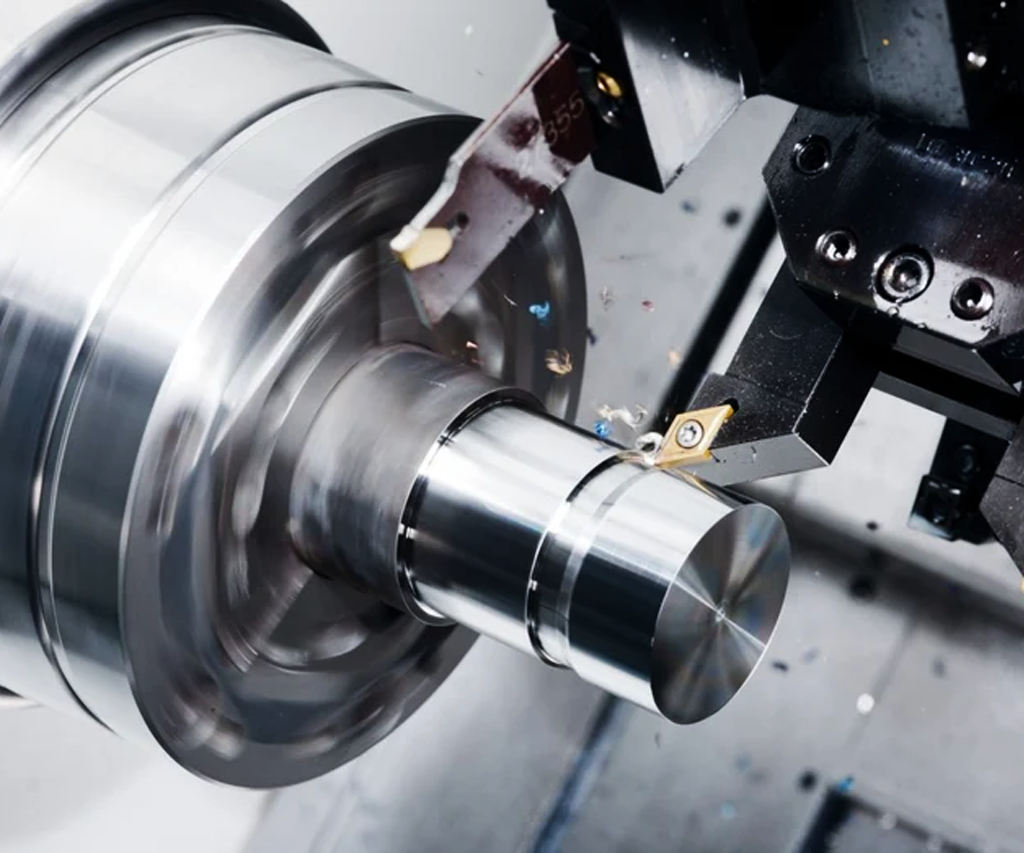

CNC Lathe

OTHER SERVICES

CNC Lathe Turning

Download our Brochure

Our company profile

CONTACT US TODAY

Vo Quy

Sales Manager VIETNAM

+84 982998709

Brett McMiles

Business Development / Sales Manager INTERNATIONAL

+61 428887392

CNC Turning Technology

The process uses a single-point cutting tool that inserts parallel to the material to cut. The material is rotated at changing speeds and the tool cutting traverses to create cylindrical cuts with exact measurements. It is used to create circular or tubular shares from larger material pieces. It is an automated process and speeds can be adjustments for greater accuracy rather than turning a lathe by hand.

Computer Numerical Controlled Accuracy.

Parts can be easily scaled.

Consistency.

Ideal for repetitive identical parts.

Cost effective machining.

Great surface finishes with high tolerances.

Our Machines

Model: OKUMA LB15-II-M : OSP U100L

YEAR: 1997

CHUCK SIZE: 254m

X TRAVEL: 150mm

Z TRAVEL: 1000mm

SPINDLE SPEEDS: 3,800 RPM

TURRET TOOL STATIONS: 12

TAILSTOCK TAPER: MT-5

MAIN MOTOR: 15 HP / CONTINUOUS 30 HP PEAK

Model: LB-25

Serial: 9484

Control: Okuma OSP-5020L Control

Chuck: 15″ 3 Jaw

Bore: 4″ (+/-)

Swing Over Bed: 18.9″

Distance Between Centers: 27.4″

Spindle Speed: 65-3500 RPM

Spindle Motor: 15kW

Distance Between Centres: 50″

Turret: 12 Station with tooling

Voltage: 220/440VV 3ph 60hz (33.5KVA)

Hydraulic Tailstock

Chip Conveyor

Coolant System . Coolant Tank

Automatic Lubrication System

Foot Operated Control

Dimensions: 135″ x 76″ x 80″

Dimensions: 170″ x 76″ x 80″ (w/ Chip Conveyor)

Weight: 12,500 lbs approx.

CNC control: OSP 5000L-G CNC System (German)

Data transmission: RS232

Tool revolver: 12-position, BOLT ON type

Lathe chuck: 250 mm

Spindle: 70-3800 rpm. (11 kw, 30 min; 7.5 kw – continuous operation) . Non-through spindle

Spindle bore diameter: fi 75 mm (at a depth of 70 mm, measured from the face of the lathe chuck and without jaws)

Spindle bore diameter: fi 28 mm (at a depth of 200 mm, measured from the face of the lathe chuck and without jaws)

X axis travel: 400 x 0.001 mm

Z axis travel: 500 x 0.001 mm

Cutting speed XZ: 0.01-1000 mm / rev.

XZ feed: 12,000 mm / min.

Power supply: 3 x 400V

Machine rated power: 21 kva

Maximum load current: 36A

Machine dimensions (width x depth x height): 2.9 (3.9 m with chip conveyor) x 1.8 x 1.72 m

Machine weight: 4500 kg

Manufactured new: 1984

Swing over bed: 400mm

Maximum turning diameter: 300mm

Maximum work length: 250mm

X axis travel (upper turret): 160mm

X axis travel (lower turret): 110mm

Z axis travel (upper /lower): 520mm

Rapid traverse rate x axes: 200 ipm

Spindle nose: a2-6

Spindle bore: 56mm

Maximum bar capacity: 45mm

Spindle speeds: 65 – 3500 rpm

Spindle motor: 30 hp

Turret capacity (upper / lower): 8 / 8 station turret

Approximate dimensions: 3556mmLx2032mmWx2159mmH

Machine weight (approximate): 13,000 lbs

Frequently Asked Questions

There are various types of turning operations that can be carried out on CNC lathe and turning centre machines, all of which have different use cases that are dependent on the design of the part to be machined. Each machine operation will have its own unique tooling which will be decided upon based on the design and specifications required.

Some of these operations include: Step Turning . Taper Turning . Chamfer Turning . Countour Turning . Facing . Grooving . Parting . Threading . Knurling . Drilling . Reaming . Boring . Tapping.

What materials can be turned?

Almost any material can be used in a CNC machine. It really depends on the application. Common materials include metals such as aluminum, brass, copper, steel, and titanium, as well as wood, foam, fiberglass, and plastics such as polypropylene, ABS, POM, PC, Nylon, etc.

What is the biggest size you can turn?

We have 4 different sized CNC lathes and our larges can swing 480mm (18.9″) in diameter and 695mm (27.4″) long.

What accuracy can be achieved from your lathes?

Our CNC lathes can achieve precision levels as tight as ±0.0127 mm (±0.0005″). This level of accuracy is essential in creating components for critical applications like aerospace, medical devices, and automotive manufacturing.