Robotic Welding

OTHER SERVICES

Robotic Welding

Download our Brochure

Our company profile

CONTACT US TODAY

Vo Quy

Sales Manager VIETNAM

+84 982998709

Brett McMiles

Business Development / Sales Manager INTERNATIONAL

+61 428887392

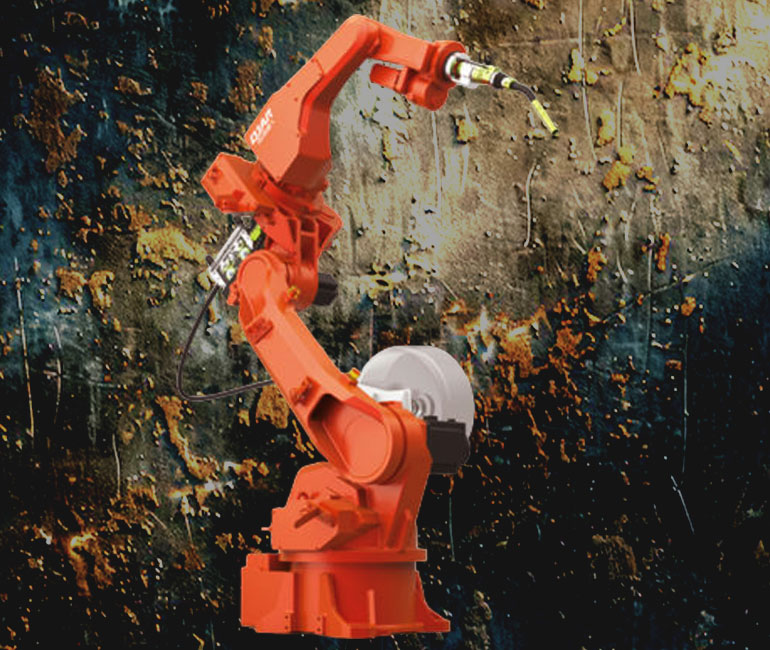

Robotic Welding Technology

Robotic welding is a highly advanced version of automated welding, in which machines conduct the welding, but welders still control and supervise the process. The use of robotic technology allows for precise and quick results, less waste, and greater safety.

Efficient and quality welds everytime.

Labour saving.

Safety for the workshop.

Consistent welds.

Our Machines

Model: TA-1600-G2

Type: Middle arm

Struture: Independent articulated

Axes: 6

Maximum allowable payload: 8 kg

Robot working area:

Max accessible distance: 1598

Min accessible distance: 360

Momentary maximum speed:

Arm Rotation (RT): 2.97 rad/sec (170/sec)

Upper arm (UA): 2.97 rad/sec (170/sec)

Front arm (FA): 3.05 rad/sec (175/sec)

Wrist: Rotating (RW) 6.28 rad/sec (360/sec)

Bending (BW) 6.11 rad/sec (350/sec)

Twisting (TW) 9.42 rad/sec (540/sec)

Positioning repetition precision: 0.1mm or less

Brake: all axis are provided with brakes

Installation: floor ceiling (factory option)

Weight of manipulator: Appox.180 Kg

Axle head load capacity: 6.4 Kg

Arm load capacity: 10 Kg

Reach: 1,410 M

Number of axles: 6

Protection level: IP30

Installation: On the floor, downward slope

Control cabinet versions: single cabinet

Physical properties:

Base size: 300x300mm

Robot weight: 150 kg

Performance (according to ISO 9283)

Position repeatability: 0.03mm

Path repeatability: 0.35 mm

Electrical connection: 380/50~60 Hz

Welding source connection: Regular black steel: EHAVE CM350AR, EHAVE CM500AR

Welding source for white steel, Aluminum: Arsten Plus 350QR, Arsten Plus 500QR