EDM Wire Cutting

OTHER SERVICES

EDM Wire Cutting

Download our Brochure

Our company profile

CONTACT US TODAY

Vo Quy

Sales Manager VIETNAM

+84 982998709

Brett McMiles

Business Development / Sales Manager INTERNATIONAL

+61 428887392

EDM Wire Cutting Technology

The Wire EDM (Electrical Discharge Machining) process uses an electrical spark created between two conductive parts, a wire that cuts and a part from which material will be removed. Using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed contour, a Wire EDM machine can produce extrusion dies, blanking punches, precise molds, special parts with small features and many more. These parts are generally cut out of hardened steel but many other materials like brass, aluminium & copper can alse be machined this way. Wire EDM is a very precise but slow machining technique.

Cuts any conductive material.

Very accurate to the detail.

Achieve complex features at an affordable price.

Cuts through thick hardened metals & tool steels.

Cut complex shapes with precise detail

Non-wearing for a flawless edge finish

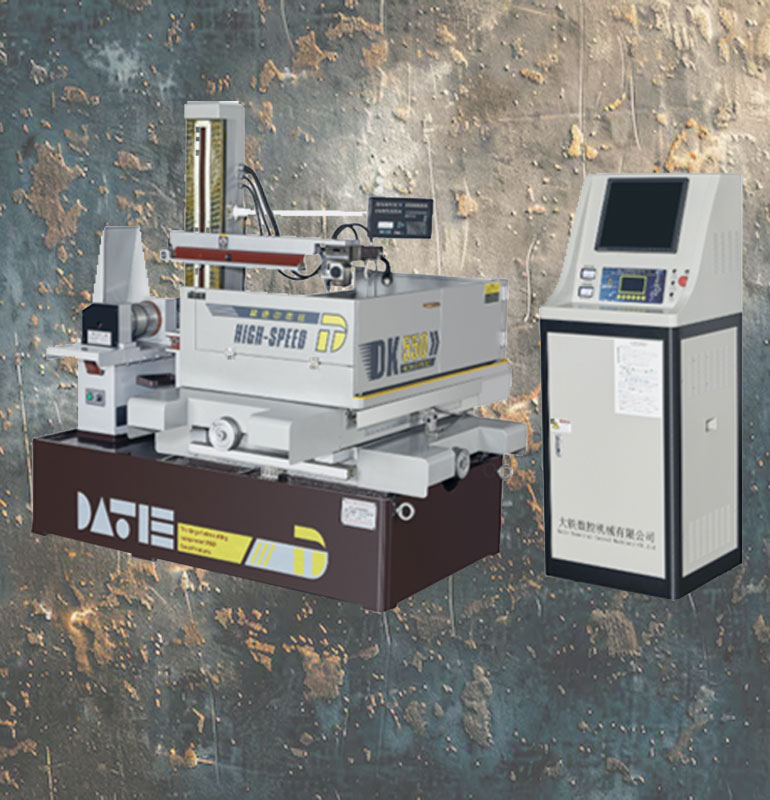

Our Machines

Model: DK450

Table size (mm): 820x560mm

Machining stroke Y*X(mm): 550x450mm

Cutting height Z (mm): 500mm

Workpiece weight (kg): 400mm

Machining accuracy (mm): ≤ 0.015

Gloss of machined surface: ≤ 2.0 µm

Maximum cutting speed: 300mm2/min

Multiple cutting speed: 7200mm2/h

The glossy surface is cut many times out: ≤ 1.0 µm

Standard taper cut: ± 6°/ 80mm

Cone shaft travel U*V(mm): 60x60mm

Cutting wire diameter (mm): 0.12~0.20

Cooling method: Use a dedicated cooling head

Winding speed: Use an inverter to adjust the speed

Wire roller speed: 5-11m/s

Z axis control: Automatic up and down motor

Machine case size (mm): 1750x1600x1700

Electrical cabinet size (mm): 640x550x1610

Machine weight (kg): 1600/1750

Power consumption (Kva): ≤ 2.5

Power supply: 380v/50hz

Operating system: Autocut/X8/HL/HF

Model: BHV-7750

Worktable size (LXW): 600x800mm

Stroke (X,Y): 550x450mm

Max Z axis travel: 500mm

Cutting angle: ±-3° °/80mm

Max cutting Speed: ≥ 90(High speed ≥200)mm2/Min

Optimum roughness: ≤ 2.5(Medium speed ≤1.0)m

Dia of molybdenum wire: 0.1-0.3(Recommend 0.18)mm

Working coolant: DX-1 ,DX -4, NG-1

Process accuracy: According to the GB7926-2005 Standard)

Feeding pulse equivalent: 0.001 mm

Power supply: Single phase ,220V/Hz, Three Phase , 380V/50Hz

Power consumption: < 1.0KW

Max workpiece weight: 450kg

Weight: 1620Kg

Dimension: 1700x1400x1700mm

Frequently Asked Questions

Wire EDM Machining, as perceived by many is not at all a new technique on the block, instead, it has been around since the late 1960s. The machining plays a predominant role in precisely cutting work pieces made from a number of conductive materials.

What’s the maximum material thickness you can cut?

Our machines have the capability to cut most materials up to 500mm thick.

What materials can you cut?

We can cut anything capable of conducting electricity, including: Inconel, titanium, aluminum, stainless steel, carbon steel, carbide, brass, copper and more.

How accurate is Wire EDM?

Our state-of-the-art EDM machines have positioning and contour accuracy of +/- 2 microns (0.00008”) which means they are more accurate than we can effectively measure.

What kind of surface finish can you obtain with Wire EDM?

We do three kinds of cuts: rough cuts, finish cuts and surface finish cuts. With polish passes, we can get down to Ra 0.08µm for many materials, eliminating the need for additional finishing operations. The end result is a finishing that’s super smooth at a microscopic level. (With additional operations, we can achieve a mirrored finish of 2 µin.)

How big of a part can you cut?

We can cut parts using x, y, z travels of approximately 500mm in the X, 450mm in the Y, and 500mm in Z.