Hydraulic Presses

OTHER SERVICES

Hydraulic Presses

Download our Brochure

Our company profile

CONTACT US TODAY

Vo Quy

Sales Manager VIETNAM

+84 982998709

Brett McMiles

Business Development / Sales Manager INTERNATIONAL

+61 428887392

Hydraulic Press Process

A hydraulic press works on the principle of Pascal’s law, which states that when pressure is applied to a confined fluid, the pressure change occurs throughout the entire fluid. Within the hydraulic press, there is a piston that works as a pump, that provides a modest mechanical force to a small area of the sample. There is also a piston with a larger area, which produces a larger mechanical force.

Smooth Pressing.

Consistency.

Simplistic.

Pressure Control.

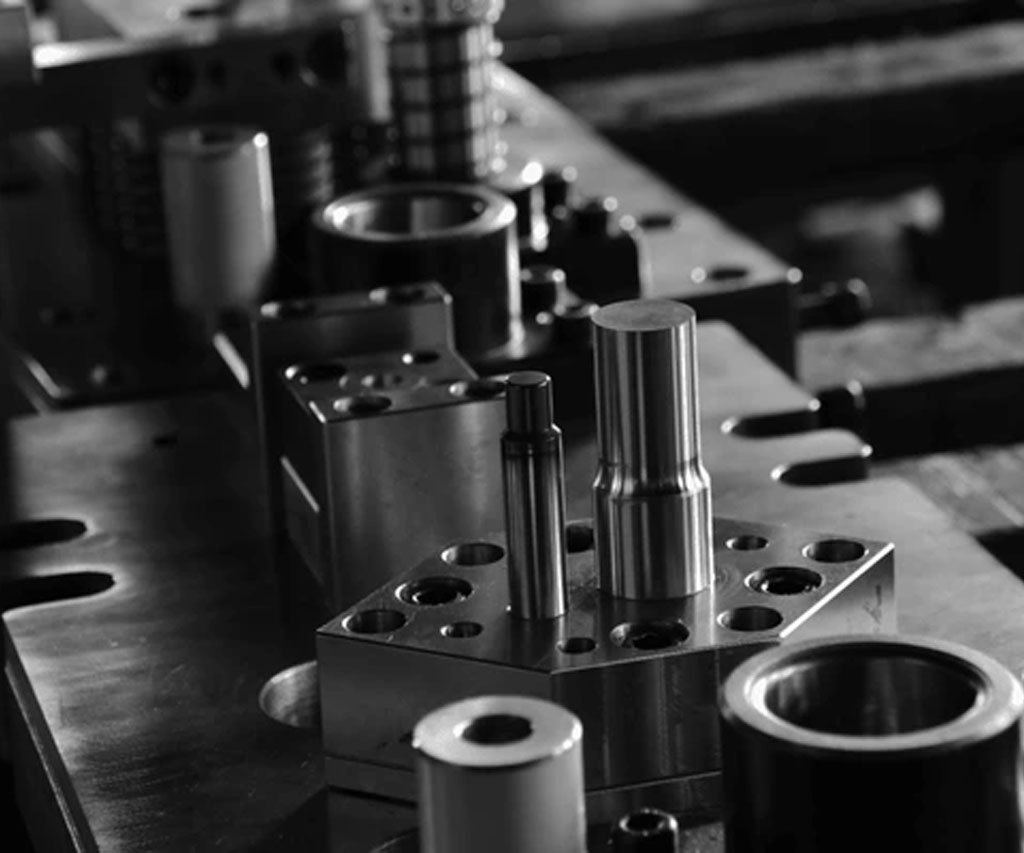

Our Machines

Dimensions (L*W*H): 1300x800x3700mm

Product name: 315T 4 column hydraulic press machine examples price

Keyword: 4 column hydraulic press

Function makes workpiece molding

Pump station size: 1300x1300x1200 mm

Color as customer request

Operation table size: 380x380x910 mm

Usage: Metal Processing

Type: vertical

Material: Steel

Country of manufacture: Japan exports to USA

Pressing force: 60.5 tons

Stamping stroke: 140 mm

Stamping frequency: 45~85 S.P.M

Size of upper table: 480×400 mm

Size of lower table: 870×520 mm

Upper table adjustment range: 70 mm

Mold opening: 300 mm

Body shape: C

Body material: Steel

Engine power: 5.5 kW

Machine weight: 5 tons

Dimensions (LxWxH): 1.6×1.2×2.5 m

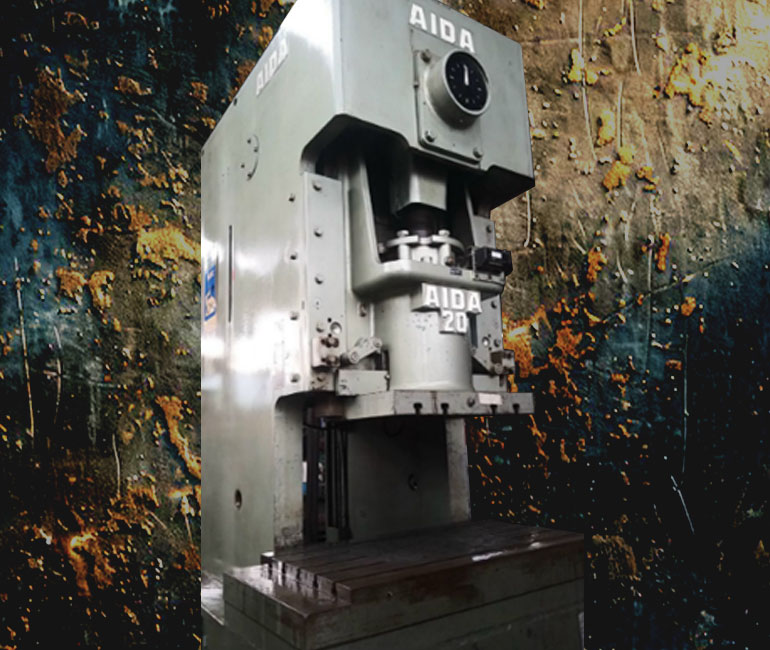

Make: Aida

Capacity: 200 tons

Bolster: 2000 x 1220

Slide: 1830 x 1000 mm

Stroke: 300 mm

SPM: 15 – 25

Die Height: 850 mm

Adjust: 430 mm

Main Motor: 22 Kw

Die Cushion: 16.7 x 2

MODEL: TP-110

SKU #: 1390

Made in: Japan

Year: 1988

Stamping force: 110 tons

Stamping stroke: 200mm

Frequency of stamping: 40-60 beats/minute

Upper table size: 520 x 620mm

Bottom table size: 610 x 1100mm

Engine power: 7.5KW

Machine weight: 11 tons